3D printing (MJF) – polymers

MJF technology combines the advantages of manufacturing by traditional methods such as injection molding with the flexibility of 3D printing.

Sounds good?

Technical data // Examples

3D printing in plastics (MJF)

HP MJF (Multi Jet Fusion) Technology.

Check all parameters (material data sheet in PDF file) ↗

- Materials: polyamide 12 (PA 12), polyamide 11 (PA 11), thermoplastic polyurethane (TPU)

- A perfect alternative to injection molding for short- and medium-volume production.

- Excellent precision and repeatability – part thickness as low as 0.5 mm.

Check our Design Guidelines (PDF file) ↗ - Maximum build volume: 380mm x 284mm x 380mm (we can cut larger parts into pieces and combine them in post-production).

- It stands up well to additional treatment – sandblasting and cleaning as standard; optional chemical staining, application of special coatings.

We meet your goals

You can count on us

Did you know that we can support you in every stage of production? We advise, optimize, prototype and model even based on drawings. If you want to copy or improve a component you have, we can realize a 3D scan and perform reverse engineering.

Post-processing capabilities

Processing of plastic parts after printing

As standard, all of our prints undergo cleaning and sandblasting, resulting in a uniform matte gray color. Additionally, we offer the option of chemical dyeing.

Embedding threads, bearings, assembling parts consisting of multiple components? 3D printing made with MJF technology is perfect for this!

Please feel free to contact our sales department to discuss your order specifications and production capabilities.

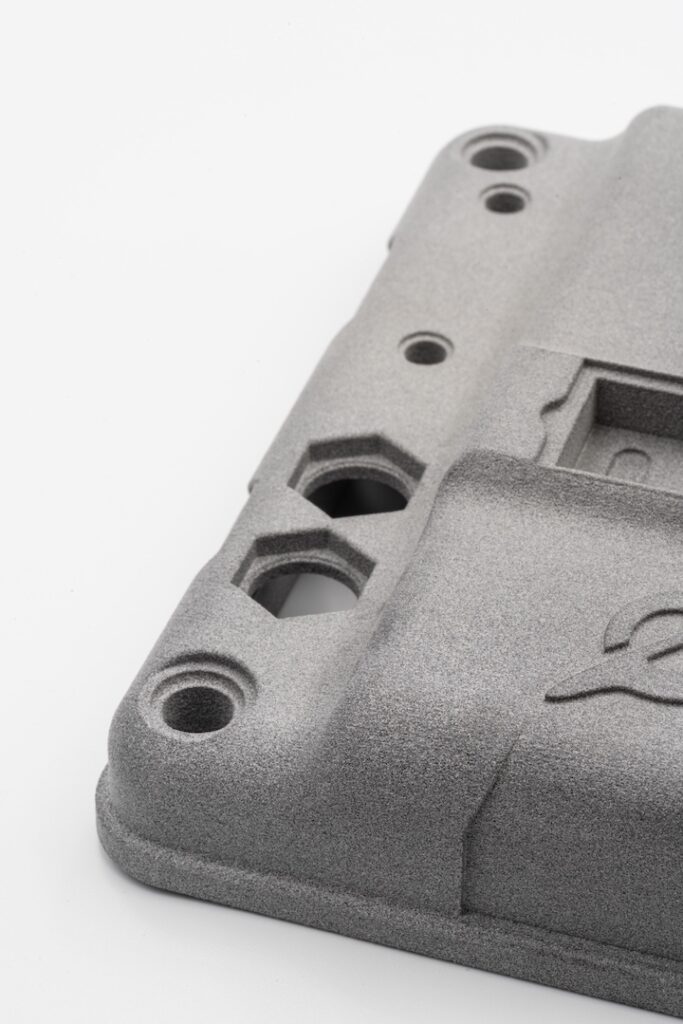

Housing of an electric motorcycle component

3D printing in polyamide 12 ( PA12 / MJF technology / HP MJF system) according to customer specifications.

Housing of an electric motorcycle component

3D printing in polyamide 12 ( PA12 / MJF technology / HP MJF system) according to customer specifications.

Specialized part – complex component with bearings

3D printing in polyamide 12 ( PA12 / MJF technology / HP MJF system) assembled with finished parts according to customer specifications.

Contact

We are ready to support you throughout the product development process – from design and prototype to mass production.

Let’s talk!

We work on weekdays from 8:00 a.m. to 4:00 p.m. (CEST)

+48 502 532 006

contact@spes3d.com

You can price your .STL or .STEP files online at any time by clicking the button.

Contact form