3D printing (LPBF) in metal

We are ready to print for you the largest Stainless Steel 316L parts in this region of Europe for you.

Sounds good?

Technical data // Examples

3D printing in stainless steel (LPBF)

Laser Powder Bed Fusion (LPBF) technology in the MetalFAB system.

Check all parameters (material data sheet in PDF file) ↗

- Materials: 316L Stainless Steel (1.4404), M300 Maraging Steel (1.2709), Aluminum AlSi10Mg, Titanium Ti6Al4V Grade 23, Inocel 625, Inconel 718

- The latest generation of metal powder sintering system.

- The strength of manufactured parts comparable to or higher than those produced using classic technologies (e.g., casting, CNC).

- Excellent precision – part thickness as low as 0.5 mm.

- Maximum build volume: 420 mm x 420 mm x 400 mm

- It stands up well to additional processing – standard sandblasting and cleaning; optional CNC, vibratory grinding, application of special coatings.

We achieve your goals

You can count on us

Did you know that we can support you in every stage of production? We advise, optimize, prototype and model even based on drawings. If you want to copy or improve a component you have, we can realize a 3D scan and perform reverse engineering.

Properties of components printed with LPBF technology

3D printing in metal – durability

The strength properties of metal prints made with LPBF technology are the same or better than parts produced in the traditional way (casting, cavity treatment). We can heat treat each printed part to eliminate any residual stresses.

The end result offers almost unlimited possibilities in industries that use lightweight and durable parts such as automotive (motorsports), aerospace or medical (precision tools, prosthetics).

Post-processing capabilities

Processing of metal parts after printing

As standard, all of our 3D prints undergo cleaning and sandblasting, resulting in a uniform, matte, dark gray finish.

If you expect special surface parameters, we can vibratory-abrasive treat the parts or machine the indicated surfaces on a CNC machine. We can also apply special coatings.

Feel free to contact our sales department to discuss your order requirements.

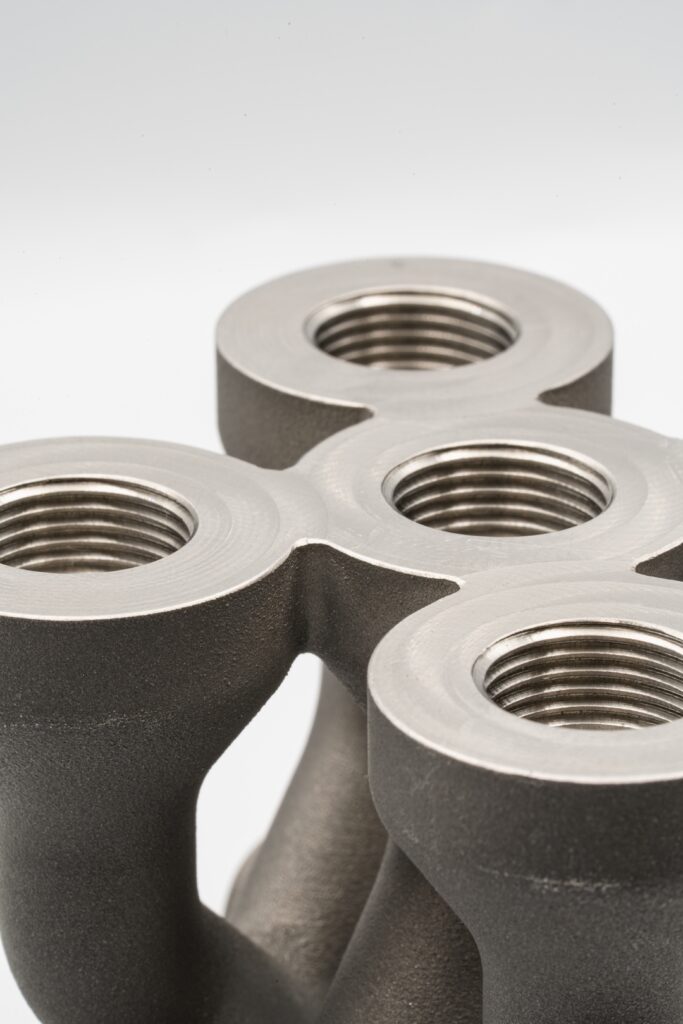

Replacement part – thread machining and surface smoothing

We processed the 3D printed parts from metal (stainless steel / LPBF technology / MetalFAB system) on-site CNC machining (post-processing) according to customer specifications.

Replacement part – thread machining and surface smoothing

We processed the 3D printed parts from metal (stainless steel / LPBF technology / MetalFAB system) on-site CNC machining (post-processing) according to customer specifications.

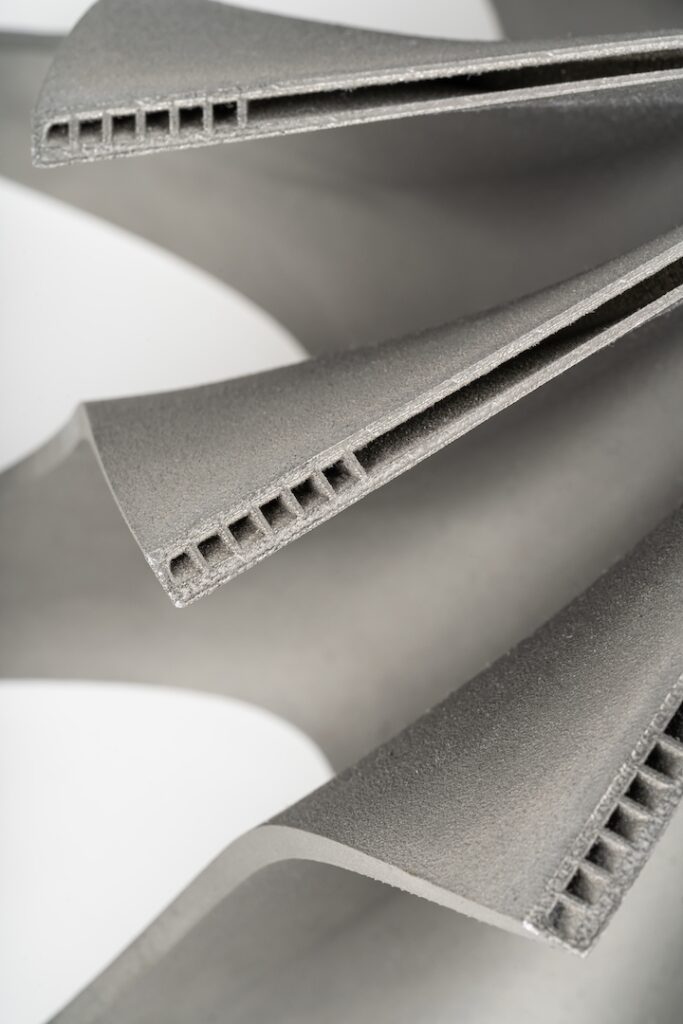

Specialized part – impeller with internal cooling channels.

3D printed metal (stainless steel / LPBF technology / MetalFAB system) subjected to on-site CNC processing (post-processing).

Contact

We are ready to support you throughout the product development process – from design and prototype to mass production.

Let’s talk!

We work on weekdays from 8:00 a.m. to 4:00 p.m. (CEST)

+48 502 532 006

contact@spes3d.com

You can price your .STL or .STEP files online at any time by clicking the button.

Contact form