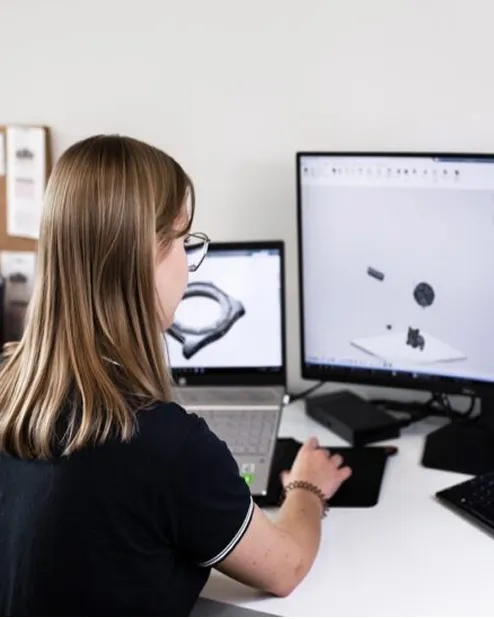

Prototypes and components for technical applications

3D printing of technical components using SLA technology

Create prototypes that faithfully reflect the appearance of the final product. SLA 3D printing with resin allows you to reproduce complex geometries and details while maintaining a smooth surface, even on a large scale.

This technology also allows for the printing of functional parts from specialised technical resins, such as ESD materials, high-temperature resins and fire-resistant resins.

Source: Formlabs, https://formlabs.com/

Source: Formlabs, https://formlabs.com/

Advantages of SLA (resin printing) technology

Precision in detail, industrial quality and advanced technical materials

SLA (Stereolithography) is an additive manufacturing technology based on photopolymerisation. The process involves selectively curing liquid resin using a precisely controlled UV laser beam, which builds the model layer by layer.

Unlike extrusion methods (such as FDM), this process allows for:

- High resolution (XY) and dimensional accuracy, which are key for reproducing complex details and geometries (important in the medical and jewellery industries, among others).

- Visual quality similar to that of a final product from an injection mould, while minimising the need for finishing.

- The ability to print from technical materials with diverse mechanical, thermal or electrical properties (such as silicone, ceramics, ESD materials, high-temperature resins, flexible or fire-resistant materials).

SLA is the preferred technology for producing visual prototypes, concept models and precision instruments, as well as for specialised applications where materials with specific properties are required.

Safe components for industrial production in EPA protected areas

ESD resin: a solution for the electronics and automotive industries

In the electronics and automotive industries, electrostatic discharge (ESD) poses a critical threat to sensitive components. Our SLA printing offering includes specialised ESD (Electrostatic Discharge) resin – a material that safely dissipates electrostatic charges, protecting components and ensuring compliance with EPA cleanroom requirements.

ESD resin is a proven solution for the production of, among other things:

- Assembly tools and fixtures (Jigs & Fixtures) for electronics manufacturing.

- Enclosures and covers for sensitive components.

- Antistatic tools and prototypes for automotive processes.

- Components for production line automation systems.

3D printing with ESD resin enables rapid concept validation and design iteration. It allows for the quick creation of final functional prototypes or custom tooling, which streamlines manufacturing processes and minimises the risk of component damage.

Transparent, flexible and high-temperature resins for special applications

Industrial resins for SLA printing

SLA technology is not only about smooth surfaces and precision details. Its key advantage is the ability to combine these features with advanced physical properties. The following materials from our range allow you to create components that simulate the properties of target production materials. They are used both for rigorous testing and as final parts for industrial applications.

Transparent resin

(Clear Resin)

They enable the creation of optical prototypes (e.g. lamp housings, optical fibres) and the validation of liquid flow. They guarantee high transparency and surface smoothness.

High-temperature resins

(High Temp Resin)

They guarantee high heat deflection temperature (HDT) and rigidity. They are used, among other things, for hot fluid flow testing and the production of tooling and short-run injection moulds.

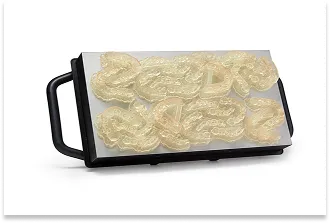

Elastic Resins

(Elastic Resin)

They simulate the properties of rubber or silicone. Ideal for the production of functional seals, shock absorbers and wearable prototypes that require flexibility.

Fireproof resins (Flame Retardant Resin)

They have self-extinguishing properties, which are crucial for flammability standards. Ideal for the production of electronics enclosures, automotive components and specialised instrumentation.

Glass-reinforced resin

(Rigid 10K Resin)

The stiffest material in the portfolio. Simulates fibreglass-reinforced plastics. Ideal for rigid jigs and fixtures and short-run injection moulds.

High impact / low friction resins

(Durable Resin)

Its characteristics include flexibility, high impact strength and low friction. This resin simulates polyethylene (PE). Ideal for compressible parts, low-friction components and jigs and fixtures that are resistant to strong impacts.

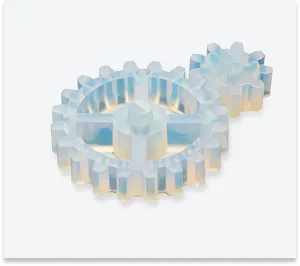

Silicone resin (100% silicone)

(Silicone 40A Resin)

The first 100% pure silicone on the market. Enables printing of soft, flexible and durable parts. Ideal for prototypes of wearables, seals, masks and chemically and thermally resistant components.

Ceramic resin

(Alumina 4N Resin)

Material with extreme thermal resistance (up to 1500°C). Ideal as an electrical insulator and for the production of wear-resistant casting tools.

Source: Formlabs, https://formlabs.com/

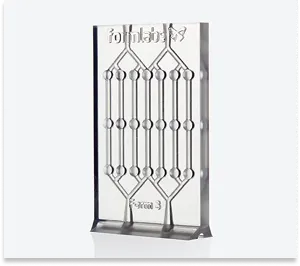

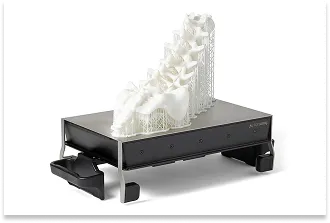

Formlabs Form 3L Reliable LFS technology

Industrial quality, large format, material flexibility

Our production is based on the Formlabs Form 3L printer, which utilises advanced LFS (Low Force Stereolithography) technology. This is an evolution of the SLA process, which ensures higher surface quality and detail precision, minimising the forces acting on the model during printing.

The key features of this device are:

- Large-format printing: the 335 x 200 x 300 mm working area allows for the production of large models or series of smaller elements in a single cycle, optimising time and costs.

- High quality and repeatability: LFS technology guarantees precise detail reproduction and dimensional repeatability with every print.

- Material flexibility: the easily interchangeable tank system allows for quick machine changeovers. This guarantees efficient access to a wide range of functional resins (e.g. silicone, ceramic, high-temperature), which increases our flexibility in implementing complex projects.

Source: Formlabs, https://formlabs.com/

Source: Formlabs, https://formlabs.com/

Examples of SLA 3D printing applications

From precise prototypes to functional industrial components

Precision, surface smoothness and access to specialised resins make SLA 3D printing suitable for many demanding areas, such as:

- Visual prototypes: creating models with a surface quality similar to the final product, ideal for presentations, design evaluation or ergonomic testing.

- Models with complex geometry: faithful reproduction of complex shapes, thin walls and fine details that are difficult or impossible to achieve with other methods.

- Functional prototypes: testing the geometry and fit of parts, especially when using specialised resins (e.g. silicone, ceramic, high-temperature).

- Production tooling (Jigs & Fixtures): rapid creation of custom assembly fixtures, holders and templates, including antistatic (ESD) tools.

- Low-volume/bridge production: manufacturing of short runs of end-use parts as an alternative to costly injection moulds.

Key 3D printing technologies for industry

Spes 3D: engineering partnership for industry

We specialise in providing professional 3D printing solutions for demanding industrial applications. What makes working with Spes3D unique?

Timeliness and efficient execution: we understand the dynamics of R&D and production processes. We operate efficiently, ensuring that orders are fulfilled and components are delivered according to the agreed schedule.

Technological versatility: we offer access to key additive manufacturing technologies – from precise SLA (resins) and efficient SLS/MJF (polyamides) to durable DMLS/LPBF metal alloy printing. We always select the optimal solution for the specifics of each project.

Industrial quality guarantee: we work exclusively with professional, regularly calibrated equipment. Our quality control process guarantees dimensional precision and repeatability of each printed part.

Engineering support: our engineers provide expertise at every stage – from consultation and geometry optimisation for the technology to selecting the ideal material.

How to order SLA resin 3D printing?

The process of ordering SLA resin printing

Step 1

Upload your 3D model

Send us your design in .STL or .STEP format. We guarantee the confidentiality and security of your design files.

Step 2

Model analysis and valuation

Our engineers will analyse the model, select the optimal printing parameters and, based on this, provide a detailed, non-binding quote.

Step 3

Acceptance and implementation

Once the offer has been accepted, we will proceed with the order. We will deliver the finished components according to the agreed schedule.

Frequently asked questions about SLA resin printing (FAQ)

The main difference lies in precision and surface quality. SLA uses a laser to cure liquid resin, allowing for much higher resolution and smoothness than FDM (fused filament fabrication). SLA is ideal for visual prototypes and parts requiring precision, while FDM is often used for less demanding functional prototypes.

Thanks to LFS technology in the Formlabs Form 3L printer and our experience, we typically achieve dimensional tolerances of ±0.2% (lower limit of ±0.2 mm) for most geometries. For specific precision requirements, please contact us for an individual consultation.

Our Formlabs Form 3L printer has a large working area measuring 335 x 200 x 300 mm. This allows for the production of relatively large models or the printing of multiple smaller elements simultaneously.

Yes. We specialise in a range of 3D printing technologies for industry. In addition to SLA (resins), we offer MJF/SLS (polyamides) and L-PBF/DMLS (metals) printing.

To prepare a quote, we require a 3D model in .STL or .STEP format. If part tolerances are particularly important, it is also worth attaching a technical drawing indicating them. Send the files.

The lead time depends on the size and number of parts, as well as the current machine utilisation. Thanks to its ability to start printing quickly and the absence of a cooling stage, SLA technology often allows for faster production than powder-based technologies. We understand the dynamics of R&D and production projects, which is why we try to be flexible with deadlines, taking into account your needs. We always confirm the estimated delivery time in the prepared offer.

Contact

Our team is at your service. We are ready to support you throughout the entire product development process – from design and prototyping to series production.

Our engineers are available on working days from 8:00 a.m. to 4:00 p.m.

Telephone: +48 882 191 184

E-mail: kontakt@spes3d.pl