Customized wristwatch

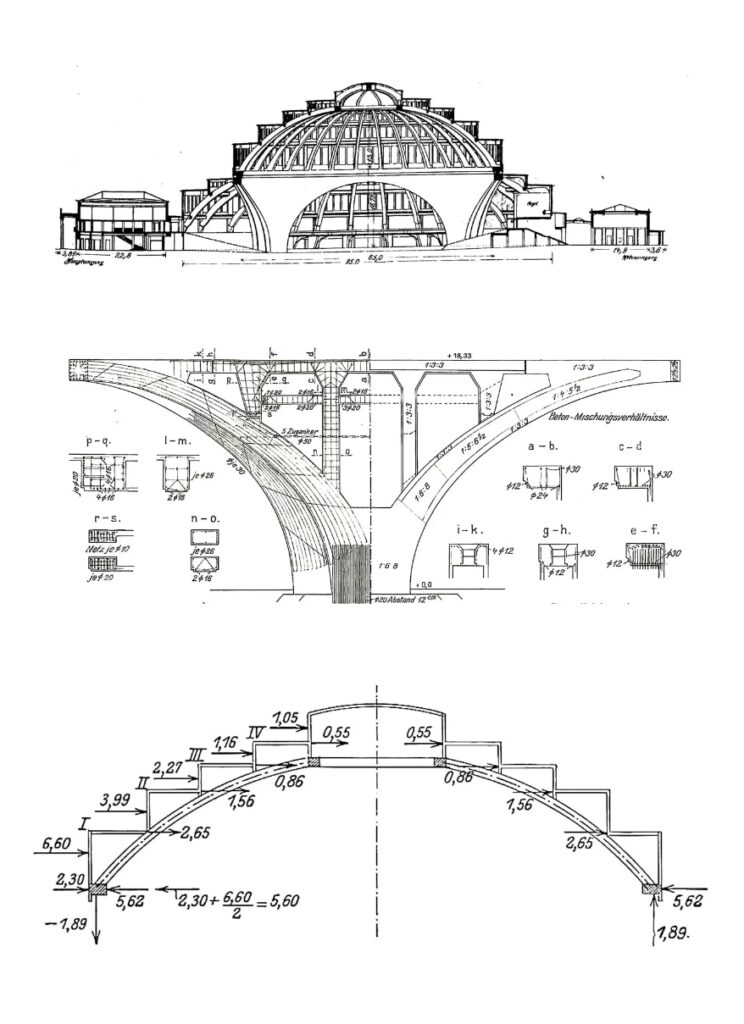

A unique watch made according to the Client’s idea. Inspired by the architecture of Wroclaw’s Centennial Hall and the Customer’s favorite basketball team.

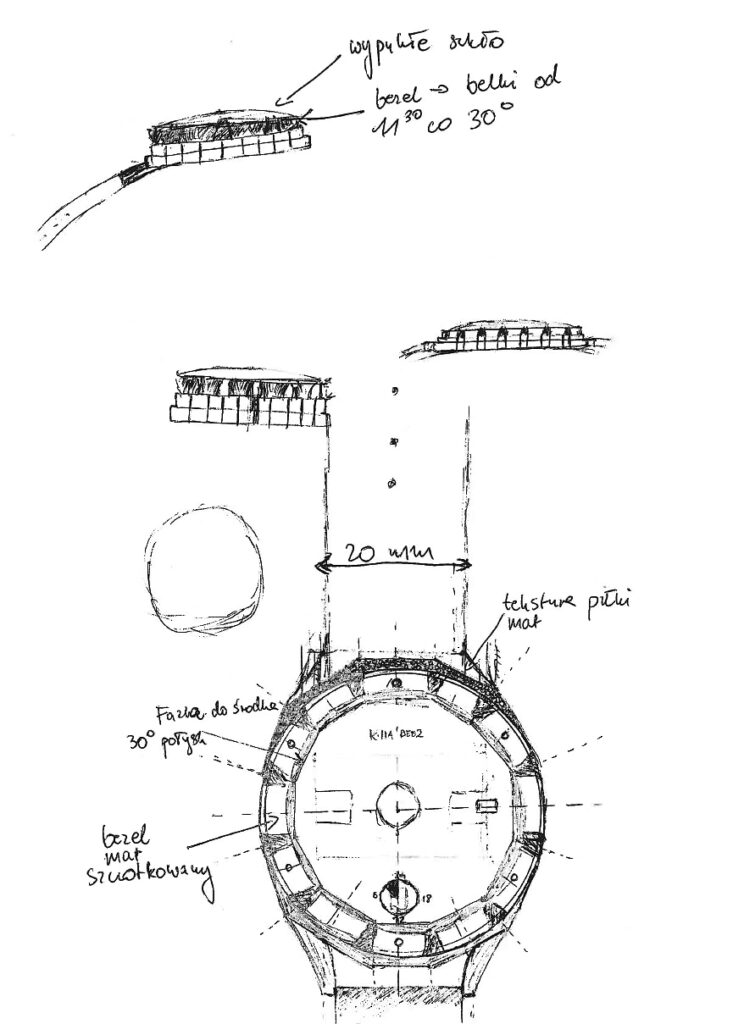

From sketch to the prototype

Our Client

The personalized watch was prompted by the interests of our client, who plays basketball for one of Wroclaw’s teams.

He provided sketches with inspiration and supervises the progress of the design and construction work on an ongoing basis.

3D printing from metal

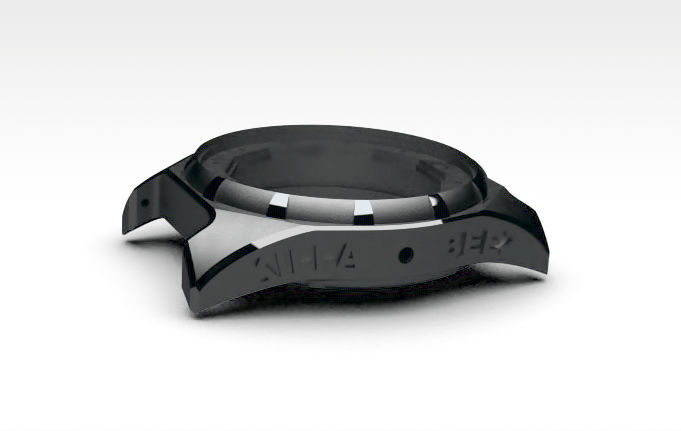

To produce the watch, we used L-PBF (Laser Powder Bed Fusion) technology, which involves sintering metal powder with a laser. Watch production requires very high precision, which 3D printing allows, reproducing the smallest details of the designed model.

Parameters

- Material: 316L stainless steel

- Weight: 48.7 g

- Dimensions: 40 mm × 48.6 mm × 12 mm

Design

Our team started working on the design of the watch based on the provided sketches. The main goal was to achieve the look desired by the client and compatibility with the selected components, i.e. mechanism, glass, strap, etc.

The design of the watch case underwent constant modifications to improve the appearance. One of the main goals was to reduce the external dimensions of the case to a minimum, as well as to reduce weight.

The design of the watch refers to the Killa Beez basketball team and the architecture of Centennial Hall.

Next steps

Weight reduction

The weight of the 316L stainless steel watch case was 43.7 grams, so in order to slim down the design we hollowed out the interior, thus reducing the weight of the case to 25.3 grams.

Water resistance

To ensure water resistance, from the underside of the watch, we used two seals between the watch case and the case back: one on the outside of the threads and the other inside the mechanism mount.

Watch mechanism

During the design process, a watch movement (Miyota 9015) was selected, for which we designed a mount that meets the manufacturer’s specifications.

Prototype I (polymer)

The first versions of the models were printed using MJF technology (HP Multi Jet Fusion 3D 4210) to try the watch on the hand, as well as to check the compatibility of the mechanism, dial, glass and strap with the watch case.

Based on polymer 3D prints of the watch case, we have made improvements to the prototype. The mechanism mount will be manufactured from PA12 material so as to optimize the weight of the watch as much as possible.

Prototype II

(stainless steel)

We made the watch case and the case back using metal powder sintering (L-PBF) technology. The process parameters of the MetalFABG2 Core printer (Additive Industries) allowed us to reproduce the smallest details of the model of 0.18 mm.

Post constantly updated.

Come back later to follow up on this project!

Print your dreams

As a team of experts in design, 3D printing and CNC machining, we offer a personalized approach to our clients’ needs.

3D printing is our passion, and with the capabilities of one of the most modern machine parks in this part of Europe, we are able to create truly unique items for you.

You do not need knowledge of specialized software. Handwritten sketches and inspiration are enough for us. Our specialists will prepare appropriate designs and files according to your guidelines.

We will advise improvements, select technology, prepare prototypes. We will refine every detail.